-

Mr. Umar JibrilWe have been cooperating with Silver Star since the year of 2011, our first chicken farm layer cage order is also very strong so far. High quality and durable cages, i am very satisfied.

Mr. Umar JibrilWe have been cooperating with Silver Star since the year of 2011, our first chicken farm layer cage order is also very strong so far. High quality and durable cages, i am very satisfied. -

Mr. BryanSiver Star battery chicken cage is worth to order: Last year we cooperated first time on hot dip galvanizing layer chicken cage. I was really surprised with the poultry cage when i recevied. What's more, Siver Star gave us more patient installation guidance. Now my farm is running very well, soon i will prepare for my second house.

Mr. BryanSiver Star battery chicken cage is worth to order: Last year we cooperated first time on hot dip galvanizing layer chicken cage. I was really surprised with the poultry cage when i recevied. What's more, Siver Star gave us more patient installation guidance. Now my farm is running very well, soon i will prepare for my second house. -

Mr. Halim SatriaIt is unforgettable for us to meet on exhibition booth, we talked with Silver Star manager Ms. Joise, and started our first business for my new chicken farms with automatic chicken cage. Ms. Joise send the engineer to guide installation for me, easy to operate, i am thankful.

Mr. Halim SatriaIt is unforgettable for us to meet on exhibition booth, we talked with Silver Star manager Ms. Joise, and started our first business for my new chicken farms with automatic chicken cage. Ms. Joise send the engineer to guide installation for me, easy to operate, i am thankful.

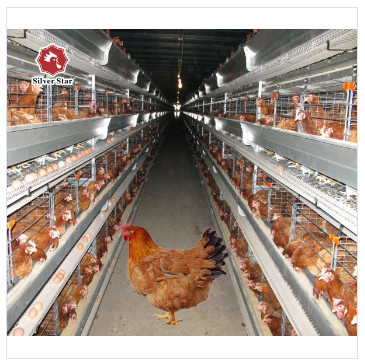

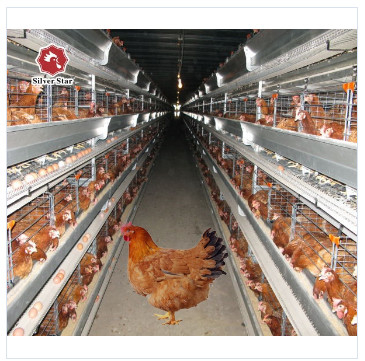

The Four-tier Battery Cage System Includes Automatic Ventilation, Housing Up To 120 Layer Chickens.

| Place of Origin | China |

|---|---|

| Brand Name | Silver Star |

| Certification | ISO9001, SONCAP |

| Model Number | H4L192/H4B208 |

| Minimum Order Quantity | 50 sets |

| Price | 150-288usd/set |

| Packaging Details | Standard exporting packaging or according to clients' request |

| Delivery Time | In 35 working days after deposit |

| Payment Terms | T/T, Western Union, L/C, D/A, D/P |

| Supply Ability | 80000sets/ month |

| Keywords | Europe Standard Battery Chicken Cage For Poultry Layers And Broilers | Each Door Size | 650x625x440, 1000x1000x440, 1500x1000x440 |

|---|---|---|---|

| Birds Capacity | 54-384 Birds/set | Cage Type | Type H Of Battery Chicken Cage |

| Marketing Type | 2021 New Type Layer And Broiler Poultry Cage | Key Selling Points | More Than 25 Years Of Lifespan |

| Surface Process | Hot-dip Galvanized Steel | Characteristics | Large Size Poultry Cage, Good Ventilation |

| Application Industries | Poultry Layer And Broiler Raising Equipment | HS Code | 84362900 |

| Highlight | 120 layer battery cage system,four-tier battery cage system,automatic ventilation battery cage system |

||

Europe Standard Battery Chicken Cage For Poultry Layers And Broilers, Good Ventilation

Introduction Of Battery Chicken Cage For Poultry Layers And Broilers:

Ensuring proper ventilation for chickens, the European standard battery chicken cage system is a significant design by Silver Star.

In the European-sized poultry layers battery chicken cage, each door measures 650mm in length, 625mm in depth, and 440mm in height, holding nine birds per door and providing each bird with 450 square centimeters of space.

Poultry broilers battery chicken cage europe size: Each door size is 1000mm length, 1000mm depth, 440mm height, 20birds/door, 500cm2/bird.

Advantages Of Battery Chicken Cage For Poultry Layers And Broilers:

1. The poultry layers and broilers battery chicken cage utilizes Q235 bridge wire, which ensures durability and resistance to bending over time.

2. Designed to be spacious, the battery chicken cage systems maintain excellent ventilation, providing a healthy breeding environment for layers and broilers chickens.

3. The high-density breeding approach using battery chicken cages for layers and broilers conserves land and investment, providing ease in bird observation and selection of weaker birds.

4.The entire array of battery chicken cage equipment undergoes hot-dip galvanized processing, which offers corrosion resistance and a lifespan of over 25 years.

5. Adequate feed, optimal water supply, and ensuring uniform health among chickens help minimize their exercise requirements, thereby conserving energy and reducing feed consumption effectively.

6. Chicken manure is completely separated from the chicken, and the manure can fall directly to the belt. The dust in the chicken house is greatly reduced, less chance of disease infection from the manure, and greatly reduce the mortality rate of birds

7. This system is suitable for both closed and open chicken houses, providing automatic control of ventilation and temperature to effectively manage challenges posed by hot weather.

8. Utilizing the belt cleaning method greatly improves air quality in the chicken house, reducing the incidence of specific diseases and ensuring a high level of safety.

9. Keeping the egg breakage rate low and ensuring high levels of cleanliness.

Specification Of European Standard Poultry Layers And Broilers Battery Chicken Cage:

| Type H Poultry Layers Battery Chicken Cage | |||||||

| Model | Door No. /cage | Chicken No. /door | No. of layers | Capacity of one set of cage | Area per bird (cm2/bird) | Each door size(mm) | Cage size/set (mm) |

| H3L54 | 1 | 9 | 3 | 54 | 450 | 650x625x440 | 650x1250x2220 |

| H4L72 | 1 | 9 | 4 | 72 | 450 | 650x625x440 | 650x1250x2870 |

| H5L90 | 1 | 9 | 5 | 90 | 450 | 650x625x440 | 650x1250x3520 |

| H6L108 | 1 | 9 | 6 | 108 | 450 | 650x625x440 | 650x1250x4170 |

| H8L144 | 1 | 9 | 8 | 144 | 450 | 650x625x440 | 650x1250x5470 |

| Full equipment | H Frame Battery Chicken Cage For Poultry Layers, Automatic feeding machine, automatic drinking system, automatic egg collection and automatic manure cleaning system, ventilation system | ||||||

| Type H Poultry Broilers Battery Chicken Cage | |||||||

| Model | Door No. /cage | Chicken No. /door | No. of layers | Capacity of one set of cage | Area per bird (cm2/bird) | Each door size(mm) | Cage size/set (mm) |

| H3B60 | 1 | 20 | 3 | 60 | 500 | 1000x1000x440 | 1000x1000x2200 |

| H4B80 | 1 | 20 | 4 | 80 | 500 | 1000x1000x440 | 1000x1000x2850 |

| H3B90 | 1 | 30 | 3 | 90 | 500 | 1500x1000x440 | 1500x1000x2200 |

| H4B120 | 1 | 30 | 4 | 120 | 500 | 1500x1000x440 | 1500x1000x2850 |

| H3B156 | 4 | 13 | 3 | 156 | 500 | 740X850X440 | 1480X1750X2800 |

| H4B208 | 4 | 13 | 4 | 208 | 500 | 740X850X440 | 1480X1750X3600 |

| Full equipment | H Frame Battery Chicken Cage For Poultry Broilers, Automatic feeding system, automatic drinking system, automatic manure removal system, automatic birds harvesting system, ventilation system | ||||||

Why Use Battery Chicken Cage In Poultry Production?

1. Lower feed wastage and boost productivity in layer poultry farming.

2. More effective flock management

3. Optimized management of the flock

4. Save on labour costs

5. No accidental deaths

6. Enhanced poultry waste management

7. The cages are designed for reuse.

![]()