-

Mr. Umar JibrilWe have been cooperating with Silver Star since the year of 2011, our first chicken farm layer cage order is also very strong so far. High quality and durable cages, i am very satisfied.

Mr. Umar JibrilWe have been cooperating with Silver Star since the year of 2011, our first chicken farm layer cage order is also very strong so far. High quality and durable cages, i am very satisfied. -

Mr. BryanSiver Star battery chicken cage is worth to order: Last year we cooperated first time on hot dip galvanizing layer chicken cage. I was really surprised with the poultry cage when i recevied. What's more, Siver Star gave us more patient installation guidance. Now my farm is running very well, soon i will prepare for my second house.

Mr. BryanSiver Star battery chicken cage is worth to order: Last year we cooperated first time on hot dip galvanizing layer chicken cage. I was really surprised with the poultry cage when i recevied. What's more, Siver Star gave us more patient installation guidance. Now my farm is running very well, soon i will prepare for my second house. -

Mr. Halim SatriaIt is unforgettable for us to meet on exhibition booth, we talked with Silver Star manager Ms. Joise, and started our first business for my new chicken farms with automatic chicken cage. Ms. Joise send the engineer to guide installation for me, easy to operate, i am thankful.

Mr. Halim SatriaIt is unforgettable for us to meet on exhibition booth, we talked with Silver Star manager Ms. Joise, and started our first business for my new chicken farms with automatic chicken cage. Ms. Joise send the engineer to guide installation for me, easy to operate, i am thankful.

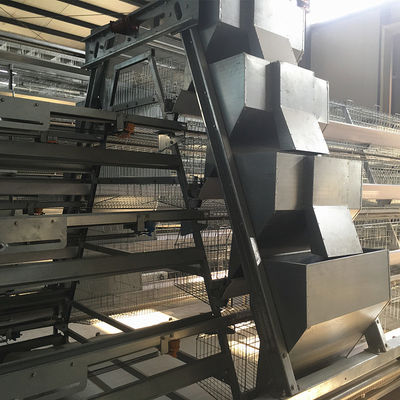

Multi Tier Automatic Poultry Feeding System For Broiler 1800x1200x410mm Size

| Place of Origin | China |

|---|---|

| Brand Name | Silver Star |

| Certification | ISO9001, SGS |

| Model Number | H4L192, H5L90 |

| Minimum Order Quantity | 30Set |

| Price | 156-280USD/ Set |

| Packaging Details | FCL: Standard exporting packaging; LCL: Wooden box, carton packaging |

| Delivery Time | in 35 working days after deposit |

| Payment Terms | T/T, Western Union, L/C, D/A, D/P |

| Supply Ability | 20000sets/week |

| Keywords | Poultry Feeding Multi-tier H Frame Chicken Cages For Layer Raising System | Cage Size | 1800x1200x410mm, 650x1250x440mm |

|---|---|---|---|

| Wire Mesh Diameter | 3-6mm, Q235 Low Carbon Steel | Wire Mesh Process | Hot Dipped Galvanized Of Layer Raising Cage |

| Cage Support | U Shaped Steel Cage Frame | Feature | Automatic Poultry Feeding Machine |

| Apply For | Livestock Animal Husbandry Equipment | Driving Motor | 380/220v, 0.75kw, Or Be Customized |

| Local Service | Ecuador, Kenya, Algeria, Indonesia, Panama, Nigeria, Ghana, Philippines, Uzbekistan, Bangladesh | HS Code | 8462900 |

| Highlight | Broiler Automatic Poultry Feeding System |

||

Poultry Feeding Multi-Tier H Frame Chicken Cages For Layer Raising System

H Frame Chicken Cages For Layer Raising System

H frame multi-tier chicken cages for layer raising system is certified by ISO9001, with scientific design and effecient working process, solid structure, and on site installation services. H type layer battery chicken cage system is produced by Silver Star can be provided from 3 to 8 floors or levels according to customers' poultry house. The surface treatment of multi-tier laying hens cage is hot dipped galvanized. We have our own wire drawing production line to produce poultry cage wires, also has the automated chicken cage wire mesh welding, cutting, bending, forming and galvanizing production line in our factory, thus we can control chicken cage quality very well by our own.

H Frame Chicken Layer Raising Farm Projects For Reference:

For 20000 Layer Birds: 139 Units/Line, 2Lines, 4-Floor, poultry house size : 100x6x4m

For 30000 Layer Birds: 139 Units/Line, 3Lines, 4-Floor, poultry house size : 100x9x4m

For 40000 Layer Birds: 139 Units/Line, 4Lines, 4-Floor, poultry house size:100x12x4m

For 50000 Layer Birds: 139 Units/Line, 4Lines, 5-Floor, poultry house size: 100x12x4.5m

(Unit Cage Size: 650mmx1250mmx440mm)

Poultry Feeding System Working Method

The hopper trolley feeding carts mode conveys the feed in the silo to the driving hopper of the poultry chicken house through the lateral feeding position. The cart runs back and forth, the homogenizer distributes the feed evenly in the feed trough, and the feed capacity can be adjusted. This process works completely in accordance with the pre-set automatic control program. With a trough with an inner edge, the chicken will not throw out the feed when eating, which saves the cost of feeding. There are feed levelers at both ends of each feed line. Regularly clean up the long-term residual feed in the trough to prevent feed deterioration and waste.

H Frame Chicken Cages Layer Raising System Specification

| H Frame Egg Chicken Cage Layer Raising Cage | |||||||||

| Model | Length(mm) | Width(mm) | Height(mm) | Cells Qty | Birds Qty/Set | Each Bird Area/cm2 | |||

| 3 Tiers | 1800 | 1200 | 2140 | 4 | 144 | 450 | |||

| 4 Tiers | 1800 | 1200 | 2790 | 4 | 192 | 450 | |||

| 5 Tiers | 1800 | 1200 | 3440 | 4 | 240 | 450 | |||

| 6 Tiers | 1800 | 1200 | 4090 | 4 | 288 | 450 | |||

| 8 Tiers | 1800 | 1200 | 5390 | 4 | 384 | 450 | |||

| 3 Tiers | 650 | 1250 | 2220 | 1 | 54 | 450 | |||

| 4 Tiers | 650 | 1250 | 2870 | 1 | 72 | 450 | |||

| 5 Tiers | 650 | 1250 | 3520 | 1 | 90 | 450 | |||

| 6 Tiers | 650 | 1250 | 4170 | 1 | 108 | 450 | |||

| 8 Tiers | 650 | 1250 | 5470 | 1 | 144 | 450 | |||

| Full Automatic Poultry Egg Chicken Farm Equipment: Poultry Chicken Layer Raising Cage Body, Automatic Drinking, Automatic Poultry Feeding, Automatic Egg Collection, Automatic Manure Faces Removal, Ventilation System, Lighting System, Environmental Controller | |||||||||

Why To Choose Chicken Battery Cage Raising Chicken ?

1. The environment of poultry chicken house is controllable, which is conducive to the physiological and production needs of chicken.

2. Automatic drinking, feeding, manure cleaning, eggs collecting, saving labors, reducing breeding cost, multi-layer chicken cage saves more space than floor raising, high land utilization rate, saving chicken house construction and land cost.

3. Due to the good isolation between the close chicken house and the outside , the chance of cross contamination of chickens will be greatly reduced, which is conducive to the prevention and control of epidemic diseases, and save the cost of epidemic prevention.

![]()